Areas of Research

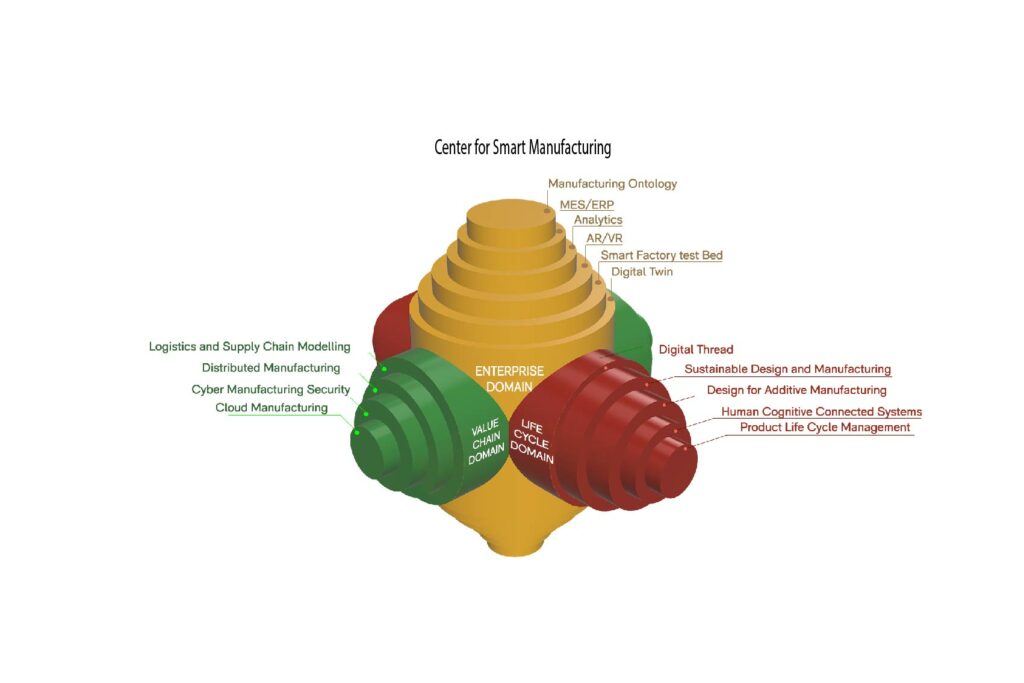

Center for Smart Manufacturing is an interdisciplinary center for IT-enabled Design and Manufacturing.

The major objectives of the center are to

- Optimize the designs by exploiting the additional complexities feasible with AM (DfAM).

- Digitize the product creation through Additive Manufacturing (AM)

- Create digital product representations of products (Digital Thread), assets, and systems (Digital Twin) suitable for smart additive manufacturing

- Capturing AM process knowledge through industry-specific manufacturing ontologies

- Create data-driven process models to leverage the data generated from the physical and virtual world (Analytics) on AM machines.

- Create augmented digital to physical spaces (AR/VR) to test early digital prototypes

- Create a scaled Smart Factory Test Bed as a proving ground for the digital AM technologies

- Build collaborative interfaces among smart manufacturing assets using cloud manufacturing

- Integrate interoperable information systems for lifecycle (PLM), enterprise (MES/ERP), and value chain domains (Supply chain and logistics) suited for smart manufacturing architectures

- Build sustainable models of design and manufacture by analyzing the cradle to grave impacts of new connected systems and products (Sustainable Product Design and Manufacturing)

- Analyze the vulnerabilities and build secure systems using blockchain architecture (Cyber Manufacturing Security).

- Decentralize the production processes and create product architectures for distributed manufacturing

- Build human-in-loop cognitive systems to bridge operation technology to information technology through Industrial Internet of Things (Cognitive IoT)